Challenges of road maintenance in underground mines

Learn more

Road maintenance in underground mines is often one of the key challenges for mining companies due to the following reasons:

- Roads without a leveling layer greatly slow down the speed of machinery, which negatively affects the output volume.

- Roads with a levelling layer are quickly destroyed by groundwater and heavy transport. Thus, rutting is formed, road renovations are required, and frequent repair works lead to forced downtime.

- Permanent roads made of concrete are very labor-consuming and expensive. Their construction requires a lot of time stalling the development of mines.

SOLUTION:

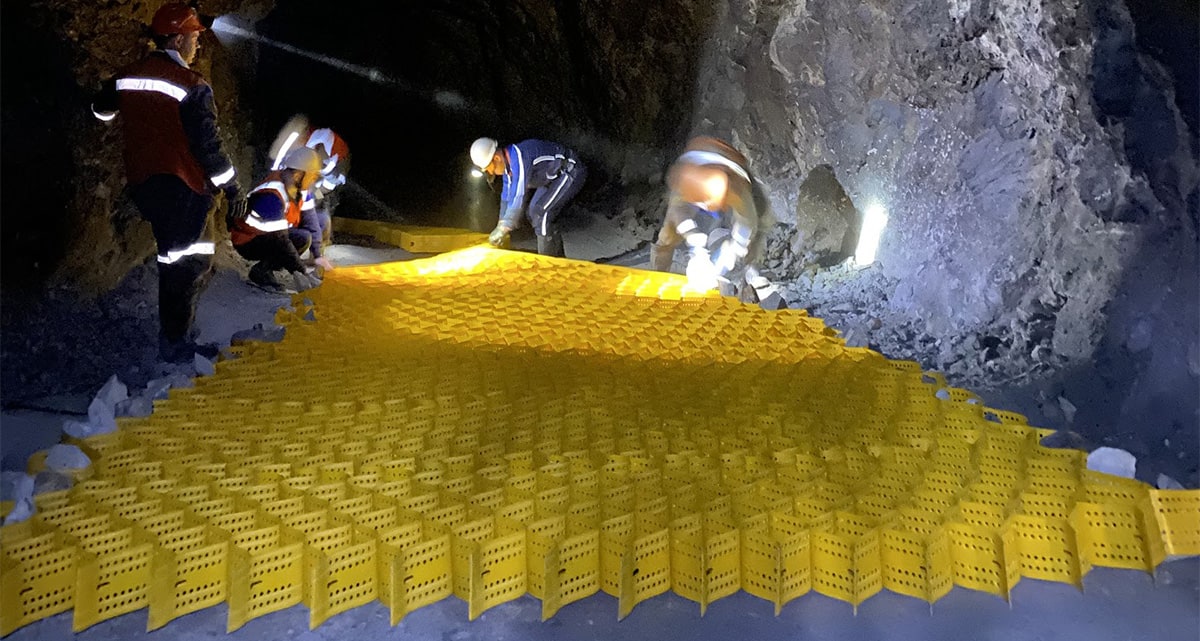

Road construction with the appliance of reinforced three-dimensional geocell GEOCORD® successfully implemented in 2018.

Request infoProject Features

Learn more

- Site: underground mine

- Base: rock formation

- Drive angle: 8–9°

- Road width: 5.5 m

- Road length: 6 180 m

- Traffic intensity: high (11 equipment units per hour, including 2–4 50t loaded dump trucks per hour)

- Watering: medium–high

- Water inflow: 140–250 m³ per hour

- Air temperature: 2–5°С

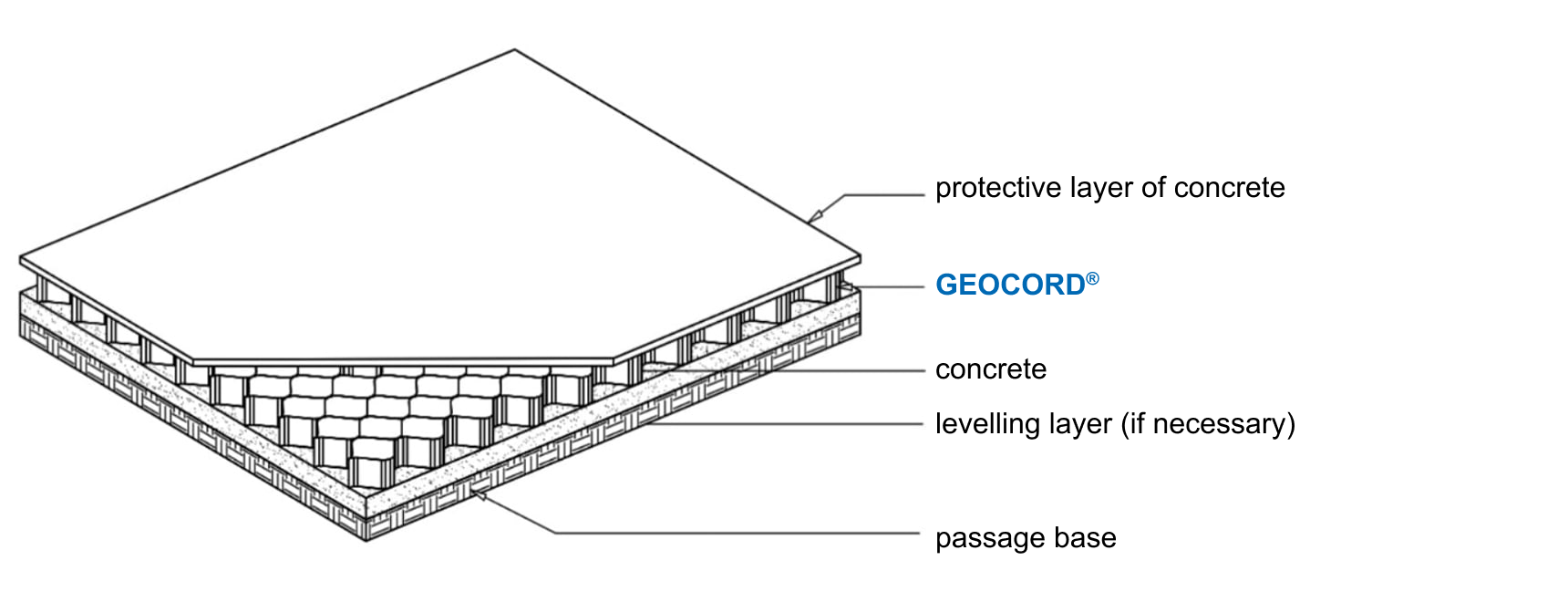

SUGGESTED DESIGN

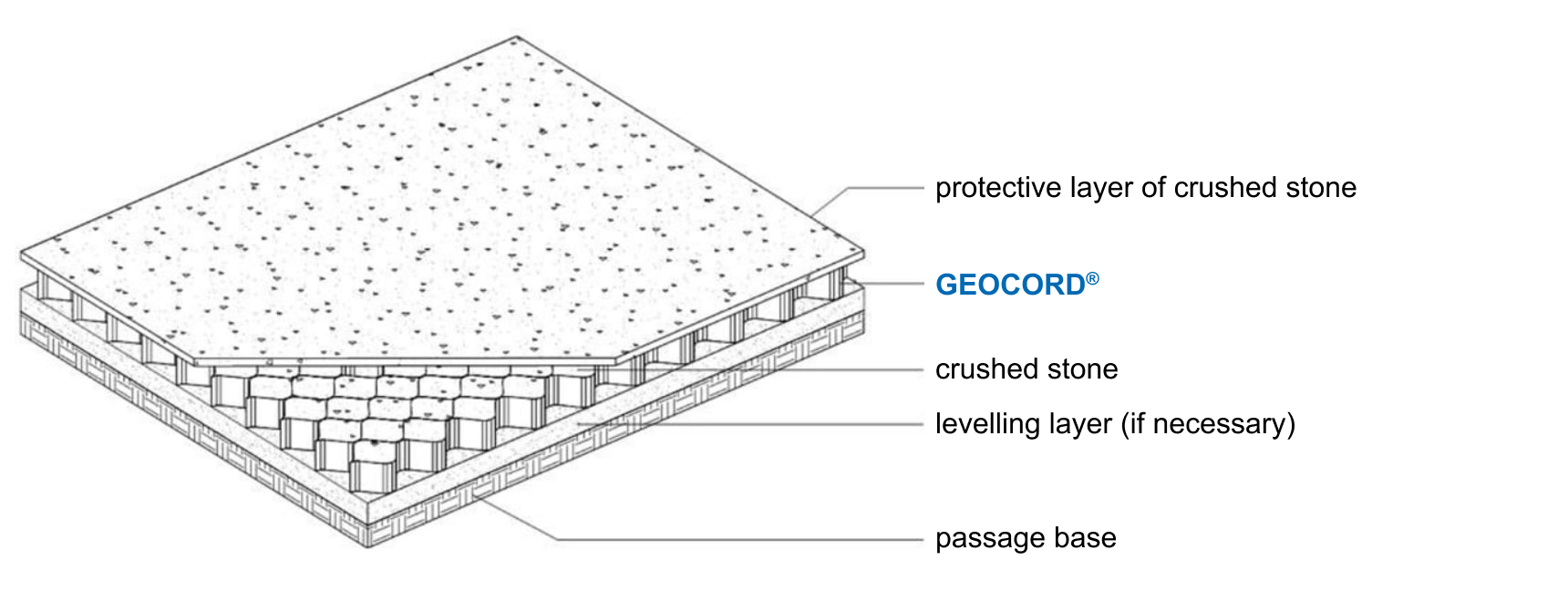

Bulk roadbed built with the reinforced geocell GEOCORD® filled with crushed stone of 20-70 mm fraction on the prepared base of crushed stone.

I have a question, call me backADVANTAGES OF THE PRESTORUS DESIGN:

INCREASED PRODUCTIVITY OF SELF-PROPELLED EQUIPMENT

- Increased speed of the machinery moving through excavations;

- Reduced non-productive downtime associated with unscheduled equipment repairs and maintenance;

- Less equipment required

REDUCED COSTS FOR MAINTENANCE OF SELF-PROPELLED EQUIPMENT

- Reduced tire wear associated with uneven ground, watered areas and foreign objects on the route of the mine workings;

- Reduced repair and maintenance costs for self-propelled equipment.

INCREASED TRAFFIC IN THE MINE

- Increased throughput capacity of the mine, which allows for more efficient use of transport excavations and planning of logistics processes.

WORK STAGES

Design with crushed stone

Construction of a road made of crushed stone with the reinforced geocell GEOCORD®.

Design with concrete

Construction of an underground route using reinforced geocell GEOCORD® filled with concrete with the addition of polymer fibers in the concrete.

What is GEOCORD®?

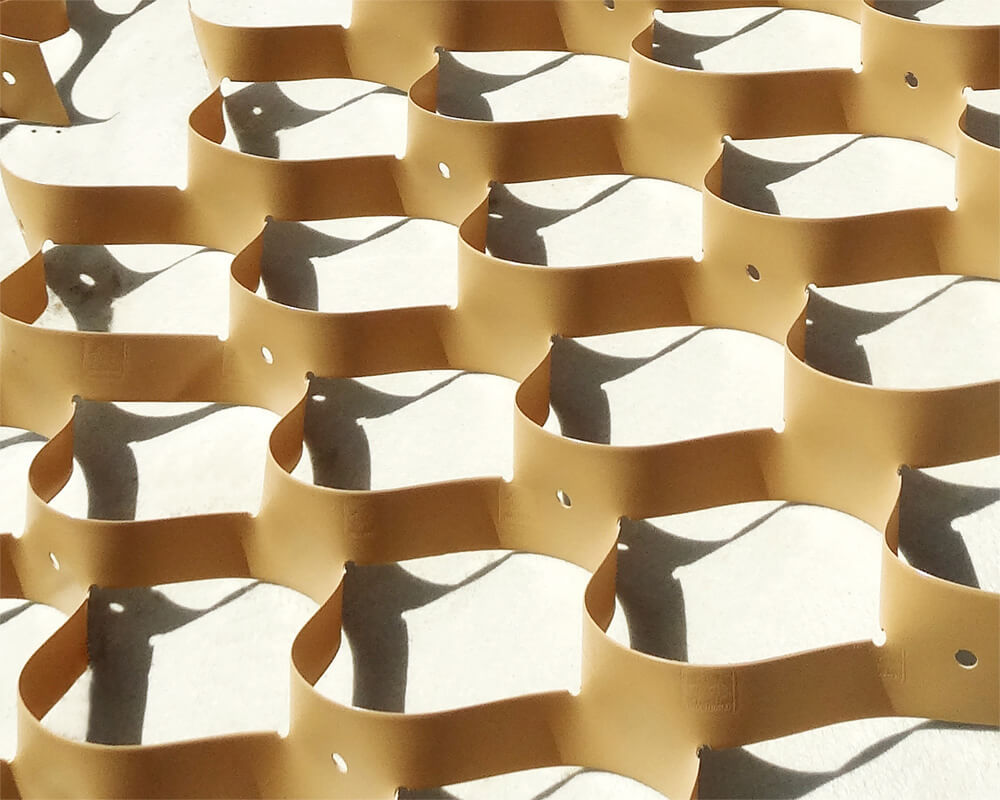

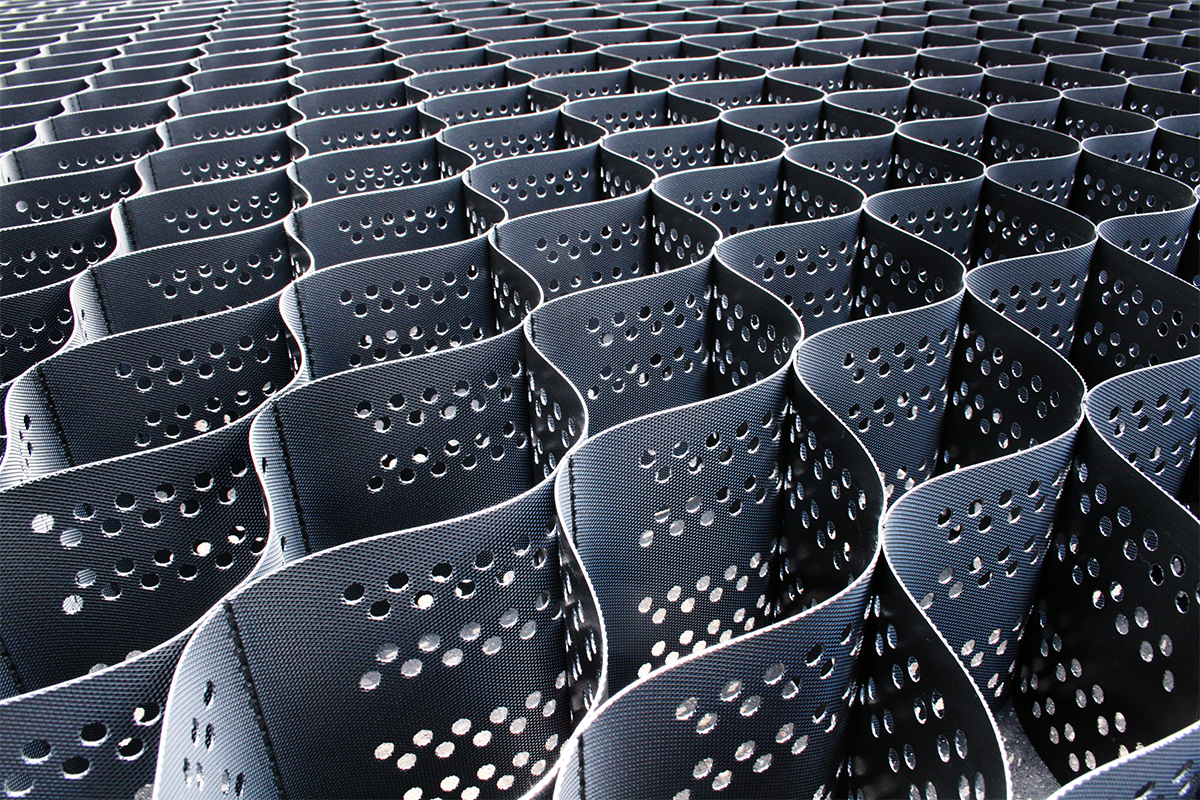

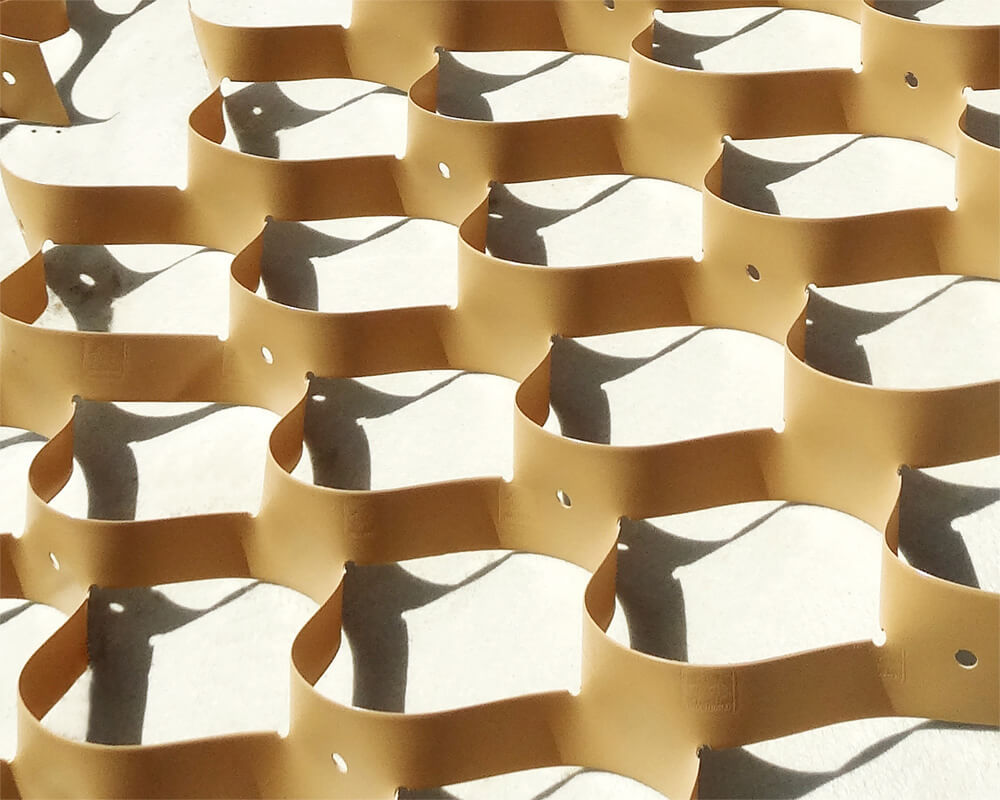

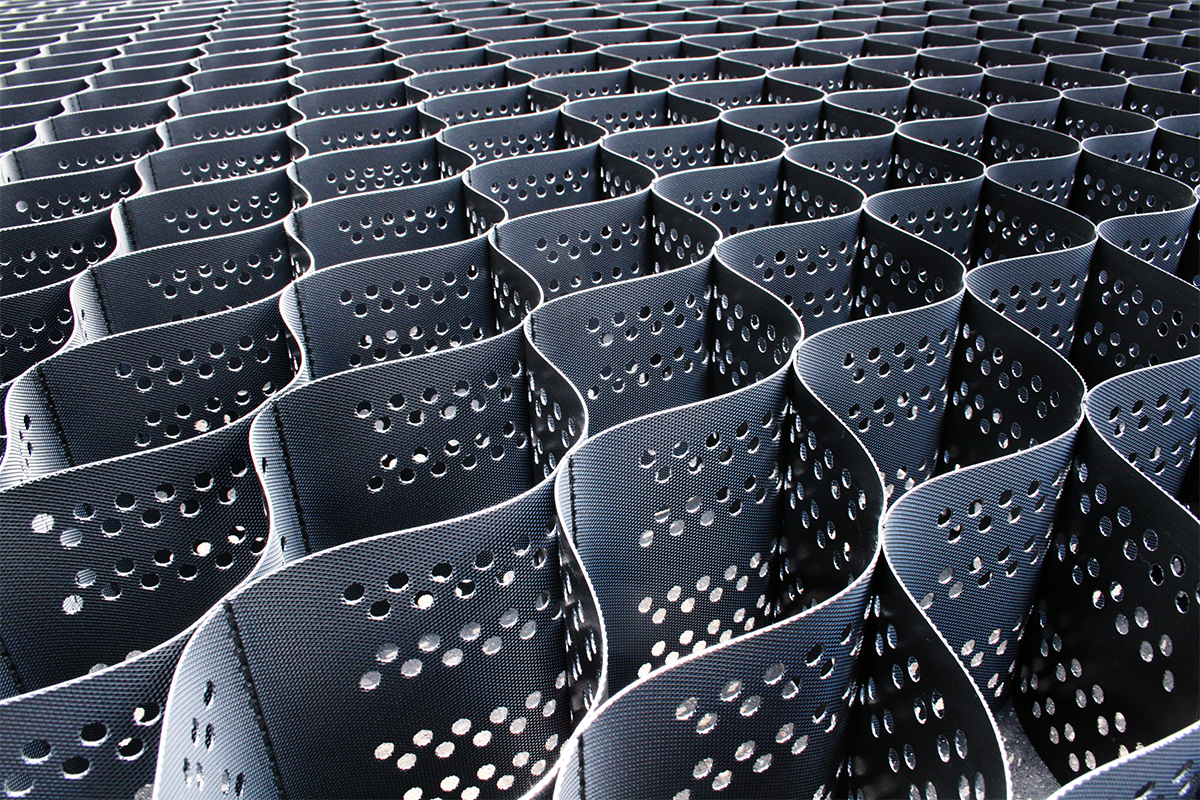

GEOCORD® is a three-dimensional geocell produced by welding polymer stripes in staggered order.

In contrast to traditional geosynthetics,

GEOCORD®‘s polymeric tapes are reinforced with high-strength synthetic fibers, providing an additional margin of safety and resistance to cell deformation under high loads.

GEOCORD® is transported to the construction site in compact modules on pallets or in bulk to minimize logistics costs.

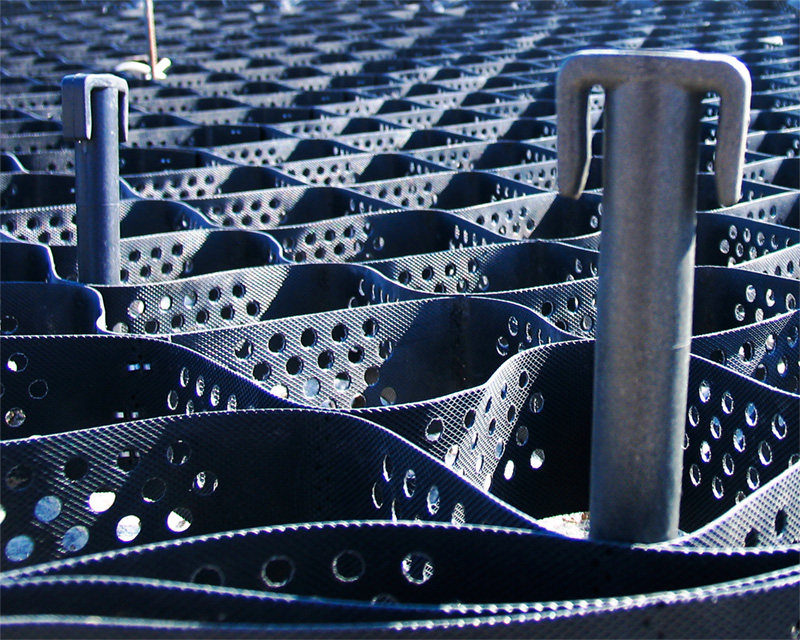

When stretched the geocell module turns into a three-dimensional honeycomb structure of a large area which is laid on a horizontal surface and fixed with anchors.

Geocells can be filled with vegetative soil, sand, crushed stone or other aggregate material depending on the requirements of the project.

Read more about GEOCORD®What Makes GEOCORD® Unique?

The reinforcing threads give the geocell increased strength and resistance to deformation under constant dynamic loads.

In other words, a design with GEOCORD® can withstand loads without deformation and last much longer. GEOCORD® is protected by international patents and recognized worldwide.

FAST-LOCK® is the fastest way to connect geocell sections.

Traditionally, the sections are fastened with a pneumatic stapler. As you know, safety requirements in mines do not always allow the use of pressurized equipment. The FAST-LOCK® fastening key is installed manually with minimal effort, which optimizes the speed of installation of geocells by 50%. It’s very convenient!

We suggest using yellow-colored GEOCORD® in yellow in low-light conditions of underground mines. The bright color of the geocells can help notice parts of the road where a protective layer of crushed stone is needed and prevent the destruction of the cells by the wheels of transport. This color can be achieved thanks to the highest quality raw materials and the use of special additives.

Tailor-made GEOCORD® perforations and strip texturing increase the bond between the aggregate material and the three-dimensional geocell, improving structural performance and increasing the reinforcement effect of the composite layer.

Cell sizes and height of GEOCORD® are selected individually based on the axial loads from the moving equipment and the traffic intensity on the site. The dimensions of the modules depend on the width of the passages in the mine.

The service life of GEOCORD® is at least 100 years from the moment of its production, which is 50% longer than that of traditional unreinforced geocells.

Our

products

More

- All

- Geocells

- Geomembrane

- Nonwoven geotextile

- Flexible Concrete Slab

- Accessories

-

Reinforced Geocell GEOCORD®

from €0.7/m2 -

Weld-free Geocell GEOSTEP®

from €0.5/m2 -

Standard Geocell

€0.6/m2 -

Flexible Concrete Slab

upon request

-

Reinforced Geocell GEOCORD®

from €0.7/m2 -

Weld-free Geocell GEOSTEP®

from €0.5/m2 -

Standard Geocell

€0.6/m2

-

Stapler and staples

upon request -

Connecting device FAST-LOCK®

from €0.05/psc -

Plastic Anchor PRUTTEKS®

from €0.25/psc -

Anchor Cord

upon request -

ARM-clip®

€0.11/psc -

Metal Anchor

upon request -

Composite Anchor GEOFORCE®

€0.35/psc -

Mounting stand for GEOSTEP®

upon request -

Mounting cross-beam for GEOSTEP®

upon request

SPECIAL OFFER:

- for road construction in mines

- for improving traffic routes

- for developing the mine infrastructure

Have a question?

If you have any questions about geosynthetics or need help with your project, fill in the contact form, and our managers will contact you shortly!

About Us

About Us