Selection of Composition and Size of Fractions of Geocell Filler Material with Allowance for Hydraulic Action

Nikita Alexandrovich Zubachev, Ilya Midkhatovich Galimov, Alexey Vladimirovich Kuzin, Olga Aleksandrovna Sobina

Introduction: While studying methods of protecting slopes from erosion effects with three-dimensional polymer geocells, we discovered the problem of the aggregate material being washed out from cells when exposed to water flow. The search for a solution to this problem was prompted by a slope collapse that took place during the construction of a stadium in the city of Volgograd (Pic. 1).

Pic. 1. Erosion of the slope under the action of rain and wastewater

Protection of the surface of the slopes is a common issue in the construction of most road, hydraulic, railway sites. The slopes are subject to constant destructive effects; i.e. all the slopes erode because of precipitation; dam slopes are affected by the flow of water, waves, and ice; railway embankments experience permanent dynamic loads [1]. Under the influence of such a number of loads, the slopes quickly collapse and the body of the embankment (structure) itself begins to deform. Due to these numerous difficulties, the constructive solution for the protection of slopes should be technologically advanced, durable, simple, and inexpensive during both installation and operation. In our opinion, three-dimensional polymer geocells could present such a solution. To prepare the study, we turned to the largest manufacturer of geosynthetic materials PRESTORUS LLC. For testing, we were provided with samples of a new generation of geocells, the innovative GEOCORD®.

At the moment there is a huge variety of three-dimensional polymer geocells on the geosynthetics market. In this article, we will not compare different three-dimensional polymer geocells, but rather talk about the effectiveness of retaining the filler material by three-dimensional geocells upon exposure to water flow, selecting the filler material and assigning geometrical parameters of a three-dimensional polymer geocell depending on the angle of inclination. Often, design engineers do not pay enough attention to this and select a filler material basing on their previous experience only and may not take into account many factors. This approach is incorrect and in this article, we have tried to tackle all the issues relating to the selection of filler material and looked into a few nuances that need to be taken into account when designing structures with the use of three-dimensional polymer geocells.

Materials and methods: The main and, perhaps, the most important function of three-dimensional geocells is the protection of the slopes from erosion caused by precipitation or other water flows. To protect the slope, the cells of the geocell are filled with various materials: sand, vegetable soil, gravel, stone, or detritus. The choice of filler material is determined by the purpose of the object, the intensity of precipitation, the flooding of the slope, the angle of the deposit, and additional loads on the slope.

An indicator of the effectiveness of the three-dimensional geocell on the slope, and, consequently, its anti-erosion function, is the ability to hold the filler material when exposed to water flow.

In order to study the retention efficiency of the filler material in three-dimensional geocells upon exposure to rain or water flow, several laboratory tests were conducted on a hydraulic installation (a hydraulic tray allows to simulate a directional flow of water at great speed, which corresponds to the real-life case of using three-dimensional polymer geocells filled with gravel) and a full-scale model of an irrigated slope (sand and vegetable soil are the most frequently used aggregates of unsinkable slopes; rain is the main source of the deteriorating effect). The purpose of the test was to determine the percentage of washout aggregate when exposed to the flow of water (in the case of using gravel as filler material) or rain (when using sand).

To study the composition and size of the filler material fractions with regard to the hydraulic impact, theoretical calculations of the critical flow velocity for a number of aggregate particle sizes were made, which were subsequently compared with the results of the experiment to measure critical velocities using water strain gauges.

The assignment of rational slope grades and geometrical parameters of three-dimensional geocells was made on the basis of calculations of critical velocities of particle drift from a slope and calculations of the stability of the geocell on the slope in accordance with [2]. We have also taken into account PRESTORUS, LLC’s experience of strengthening the slopes with geocells.

Results: Examination of the efficiency of retention of the filler material by geocells when exposed to water flow.

For the first test, the effectiveness of holding the filler material with two types of geocell was studied: perforated GEOCORD, type C 200/172 P (tensile strength — 29 kN / m; 200 mm — cell height, 172 mm — cell size on the side), and unperforated GEOCORD, type C 200/172. The cells were filled with gravel with a fraction of 20-40 mm, the slope laying angle was 1:2 and 1:1 [3,4,5]. During the tests, the samples were exposed to the flow of water at a speed of up to 2 m/s for 20 minutes, after which the amount of gravel washed from the cells was measured and the percentage loss of the filler material was determined. Three series of tests were carried out for each type of geocell and for each laying of a slope (Pic. 2).

Pic. 2. A hydraulic model for determining the effectiveness of retaining aggregate under the influence of water flow

As a result of the tests, it was established that aggregate losses averaged no more than 1% for both perforated and non-perforated geocell. However, the drainage capacity of the perforated geocell is much higher, water does not have a proclaiming effect on the aggregate and it is more stable in the cell. This result indicates high retention of aggregate-crushed stone by the bulk geocell when exposed to water flow, therefore, the bulk geocell (in this experiment, GEOCORD) has a high erosion capacity and is excellent for protecting slopes.

For the second test, geocell GEOСORD, type C 100/172 0530 P (perforated), and GEOCORD, type C 100/172 0530 (non-perforated) filled with medium-sized sand with a fraction of 2-2,5 mm, were fit onto a full-scale slope model of 1:2 and 1:1 (Pic. ##3, 4) and subjected to irrigation from rain plants with an intensity of 3 l/min * m2 for 20 minutes [##3,4,6]. Water with particles of washed sand was collected in tanks and placed in a drying chamber, and then the percentage of soil loss was determined.

Pic. 3. Full-scale model of the slope to determine the effectiveness of the retention of aggregate-sand geocell when exposed to water flow

Pic. 4. Testing process

According to the results of the tests, it was established that the loss of the filler material was no more than 15%. Given the size of the aggregate, the high intensity of precipitation, and the absence of grass sowing, it is a very good result. The geocell «GEOCORD» is capable of holding even fine aggregate well, but as demonstrated by the test results, planting grass to create reinforcement is necessary.

Selection of the composition and size of fractions of geocell filler material with allowance for the hydraulic effect

In order to effectively select the composition and fractions of the geocell aggregate, it is necessary to determine the relationship between the water flow rate and the aggregate fraction size.

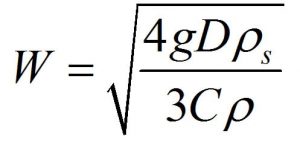

According to the formula (1) we determine the hydraulic particle size of the aggregate particles of different fractions:

where

C – coefficient of resistance, 0,45 for a spherical particle;

D – aggregate particle diameter;

ρs – particle density;

ρ – fluid density (water 1 t / m3);

g – free fall acceleration (9,81 m / s2);

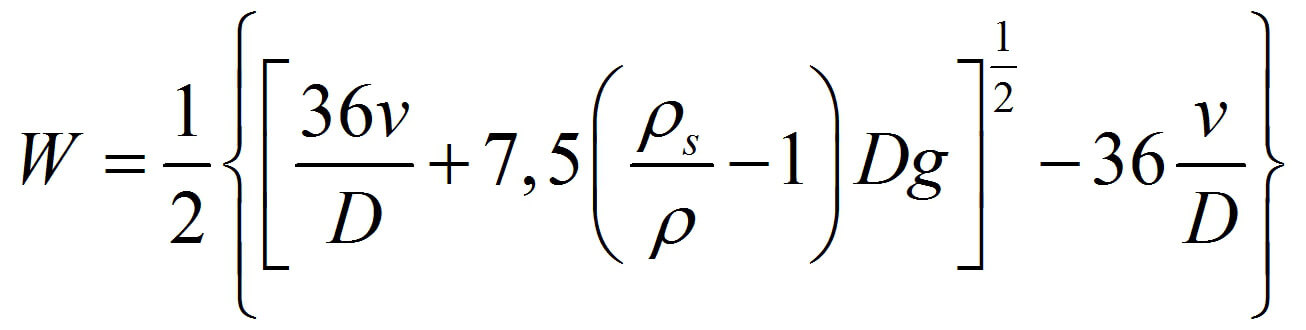

In order to factor in all modes of water movement (laminar and turbulent), as well as large sizes of aggregate particles, we use the empirical formula for calculating the sedimentation rate of suspended particles (2):

The results are summarized in Table 1 (all values were taken according to reference data [7]).

Table 1. Hydraulic size at t = 15° C (according to A.V. Vorantsov)

|

Hydraulic size at t = 15 ° C (according to A.V. Vorantsov) |

|||||||||||||

|

Diameter of particles, mm |

200 |

20 |

5 |

2,5 |

1,0 |

0,5 |

0,2 |

0,1 |

0,05 |

0,01 |

0,005 |

0,001 |

|

|

Hydraulic size, mm / s (m / s) |

3920 (3,92) |

1240 (1,24) |

620 (0,62) |

430 (0,43) |

100 (0,1) |

60 (0,06) |

21 (0,021) |

8 (0,008) |

2 (0,002) |

0,08 (8* ) |

0,03 (3* ) |

0,0008 (8* ) |

|

The next step was to determine the critical speeds at which the aggregate particles would be carried away from the slope (not protected by geocells).

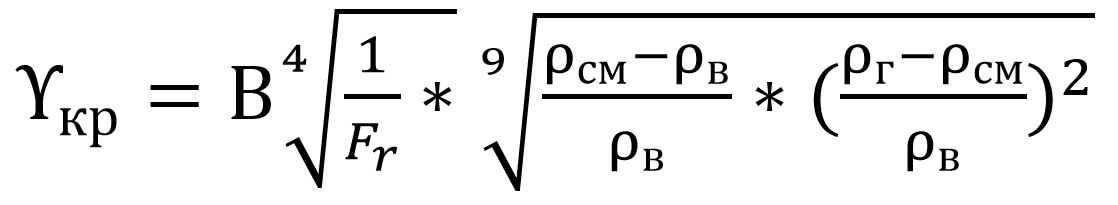

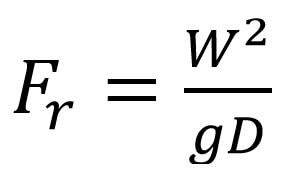

The critical speed in the pressure-free mode is calculated by the formula (3):

where

В — empirical coefficient (3,85 — sand, gravel; 2,86 — coarse clastic rock);

ρсм — mixture density;

ρв — density of water;

ρт — aggregate density;

W — hydraulic aggregate particle size. see table 1.

We summarize the results in table 2, all values were taken according to reference data [7].

Table. 2. The critical speed of particle drift on an unprotected slope

|

Critical particle demolition speed on an unprotected slope |

|

|

Soil (d mm) |

|

|

Clay particles (0,001) |

0,002 |

|

IL (0,005-0,05) |

0,1-0,13 |

|

Fine Sands (0,05-0,1) |

0,1-0,18 |

|

Sands of medium size (1-2,5) |

0,18-0,35 |

|

Large sands (2,5-5) |

0,35-0,5 |

|

Crushed stone, stone (20-200) |

2-3 |

In the calculation, the thickness of the water flow was assumed to be h = 0,5 m, slopes for water flow: 1,5–4,5% — with such slopes, particle drift is guaranteed.

Now, knowing the critical speeds of the demolition of particles of the soil of an unprotected slope, we will define this indicator for a slope protected by a three-dimensional geocell. The cells will have a major impact on the critical speeds since they resist the movement of fluid and the particles of the aggregate material will linger between the cells and, therefore, the critical particle drift velocities will decrease significantly. To determine the critical speeds taking into account the cell size of a voluminous geocell (using a GEOCORD® geocell with a cell size of 200 mm diagonal perforated) and considering its texturing, we conducted a series of tests on a hydraulic tray. Measurement of critical velocities was carried out with the help of “water” strain gauges, which are able to measure the force effect of the flow. The test results are presented in table 3.

Table. 3. Critical particle demolition speed on a geocell-protected slope

|

Critical particle demolition speed on a geocell-protected slope |

|

|

Soil (d mm) |

|

|

Clay particles (0,001) |

0,0002 |

|

IL (0,005-0,05) |

0,01-0,013 |

|

Fine Sands (0,05-0,1) |

0,01-0,018 |

|

Sands of medium size (1-2,5) |

0,018-0,035 |

|

Large sands (2,5-5) |

0,035-0,05 |

|

Crushed stone, stone (20-200) |

0,2-0,3 |

Thus, knowing the critical flow speed of water falling on a slope, one can choose the type of geocell filler material and its fraction.

Assignment of rational slope angles and parameters of three-dimensional geocells

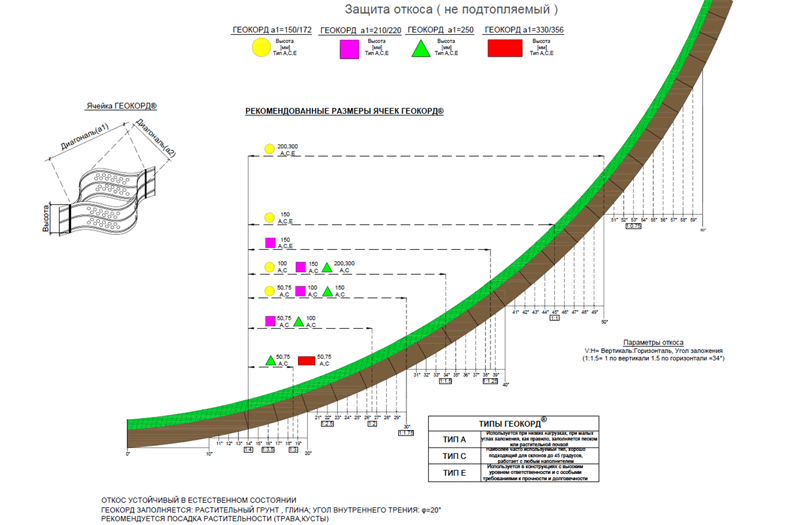

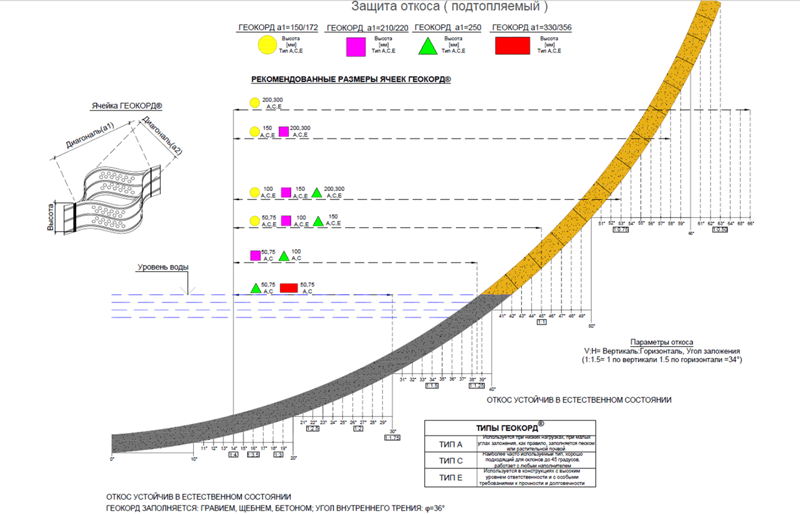

Based on the calculations of critical velocities of particle drift from the slope and calculations of the stability of the geocell on the slope [2], we recommend using three-dimensional geocell on the slope with a marginal laying of 1:0.5 (60°). Also, based on a wide experience of slope reinforcement with three-dimensional geocells, we developed a technique for selecting the parameters of a three-dimensional geocell, namely: height, cell size, wall thickness, and the slope angle. These techniques were developed for both non-flooded (Picture 5) and flooded slopes (Pic. 6). It must be remembered that the fixation of three-dimensional geocells on the slope is carried out using anchors, the number of which is determined based on the calculation.

Рic. 5. Diagram of the selection of parameters of geocell, depending on the laying of the slope (non-flooded)

Рic. 6. Diagram of the selection of parameters of geocell, depending on the laying of the slope (flooded)

Conclusion. The tests that were carried out made it possible to conclude that the cause of the destruction of slopes, among other factors, is the wrong choice of aggregate material. When designing a slope protection solution using geocells, the following recommendations should be considered:

— when assigning the parameters of slopes and types of three-dimensional geocells, prepare the design basis and do not neglect engineering surveys;

— when designing slopes with the use of three-dimensional geocells, take slope angles of up to 60°;

— choose the filling material depending on the project’s basic engineering design data;

when designing a solution for the protection of slopes against erosion, use perforated geocells in order to avoid loss of the filling material and over-wetting of the body of the slope.

Keywords: Hydrotechnics, road construction, geosynthetics, three-dimensional polymer geocell, GEOСORD, cells, slope erosion, filler material, hydraulic impact, slope laying, slope reinforcement.

Acknowledgments: The authors express their gratitude to the company LLC “PRESTORUS” and personally to Mikhail Mikhailovich Azarkh, COO for the assistance rendered during the conduct of this study.

About Us

About Us