Influence of the Strip Thickness on the Physical and Mechanical Characteristics of Three-dimensional Geocells

Author: Project Manager of the Marketing Department of PRESTORUS LLC, A.V. Krupnik

According to the research of the market of three-dimesional geocells conducted by PRESTORUS, the regulatory documentation (STO or TU) of most manufacturers contains an incorrect assertion that “The thickness of the strip can change without compromising the physical and mechanical properties of geocells”.

In order to obtain reliable information, PRESTORUS employees tested the short-term load of bands of geocells with different thicknesses in the range from 1.2 to 1.8 mm, made according to the same raw material recipe, on an Instron tensile testing machine (Fig. 1) under the same conditions stretching speed 50 mm / min.

Pic. 1. «Instron» test machine

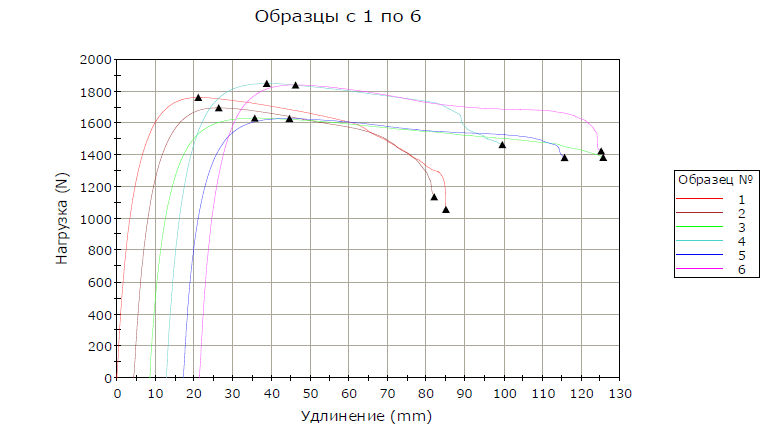

Pic. 2. Geocell tensile test process graph

In fig. 2 graphically depicts the process of deformation of the material, which consists of three stages:

- 1st stage – reaching maximum load (top of the graph);

- 2nd stage – plastic deformation (elongation);

- 3rd stage – geocell tear.

All samples 1 to 6 have different thickness:

- 1,2 mm (samples #3 and #5),

- 1,25 mm (samples #1 and #2),

- 1,3 mm (samples #4 and #6).

Judging by the schedule, samples No. 3 and 5 (with the smallest thickness of the tape) reached the maximum load (about 1600 N) faster than the others and went into the phase of elongation (plastic deformation).

Samples with a larger strip thickness showed higher maximum loads (1.25 mm — 1700 N; 1.3 mm — 1800 N). With a change in tape thickness of only 0.1 mm, the difference in the maximum load supported by the sample changes by 12.5%.

The generalized results are ordered in table 1, depending on the thickness of the strip from which the geocells are made.

Table 1

| Indicator | Unit | Value for strip thickness | ||

| 1,3 mm | 1,5 mm | 1,8 mm | ||

| Unperforated tensile strength at maximum load | kN/m | 18 | 25 | 32 |

| Tensile strength of perforated geo-strip | kN/m | 12 | 18 | 24 |

As the research results showed, the strip thickness directly affects the physical and mechanical properties of spatial polymer gratings. As a result of reducing the strip thickness from 1.5 to 1.3 mm, strength indicators are reduced by 25-30%. In other words, manufacturers mislead customers when they indicate in normative documentation that “the strip thickness can vary from 1.2 mm to 1.8 mm without deterioration of physical and mechanical properties”.

From the manufacturers point of view, this discrepancy can be substantiated by the desire to save on material and win in the competition. The customer’s point of view is such that not a single customer will understand this if all the necessary permits have been received. Therefore, there is a gap precisely in the field of regulatory regulation and control, since some of these standards have even been approved by Rosavtodor.

The only option in which it is possible to reduce the thickness of the strip without compromising the physical and mechanical properties is to introduce qualitatively new elements into the strip. This can be an improvement in the composition of raw materials, the development of innovative alloys, the use of new materials, the inclusion of additives, or the introduction of heavy-duty reinforcing threads into the strip, as the developers of the innovative Geocord spatial spatial polymer lattice (IPPR) did (Fig. 3). The test results of the new material showed that even with a strip thickness of 1.3 mm IPPO «GEOKORD» has higher performance than conventional geocells with a strip thickness of 1.6 mm without reinforcement.

The maximum positive effect of reinforcement is achieved for a geogrid weakened by perforation (the predominant majority of volume geogrids used in projects are perforated). The strength of the perforated IPOK “GEOKORD” increased by 50% compared to the standard geogrid.

The advantages of reinforcing the strip make it possible to reduce its thickness without compromising the physical and mechanical properties of spatial polymer gratings. In other words, the PRESTORUS engineers have received innovative material with high characteristics and a reduced price (15-20% cheaper due to the saving of raw materials while reducing the thickness of the strip).

About Us

About Us